Plum to prune.

A year-long journey

Prune production

Prune production is one of the very few Australian horticultural sectors that continues to grow, with farmers planting new trees every year.

A prune tree takes four-to-six-years to bear harvestable fruit. Even then, a tree needs eight to 12 years before it reaches a full production capacity. At that point, an orchard will turn out about 30 years of maintained prune production.

Winter rest

Once the trees are harvested, which can be as late as mid-April in Australia, the prune trees will start to lose their leaves.

The prune is a deciduous tree, like all fruit-bearing trees. Once the leaves have fallen and the first frost marks the start of winter the tree will become dormant.

This “quiet time” for the trees gives farmers a chance to prune the trees. Pruning is done mechanically and often finished by hand. Pruning helps to maintain tree shape, control fruit size and quality, and preserve a tree’s long life.

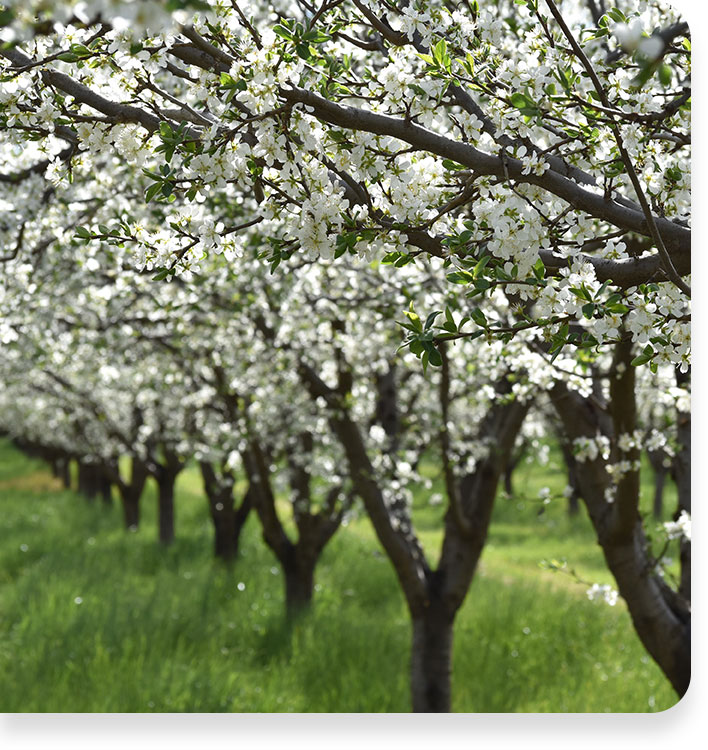

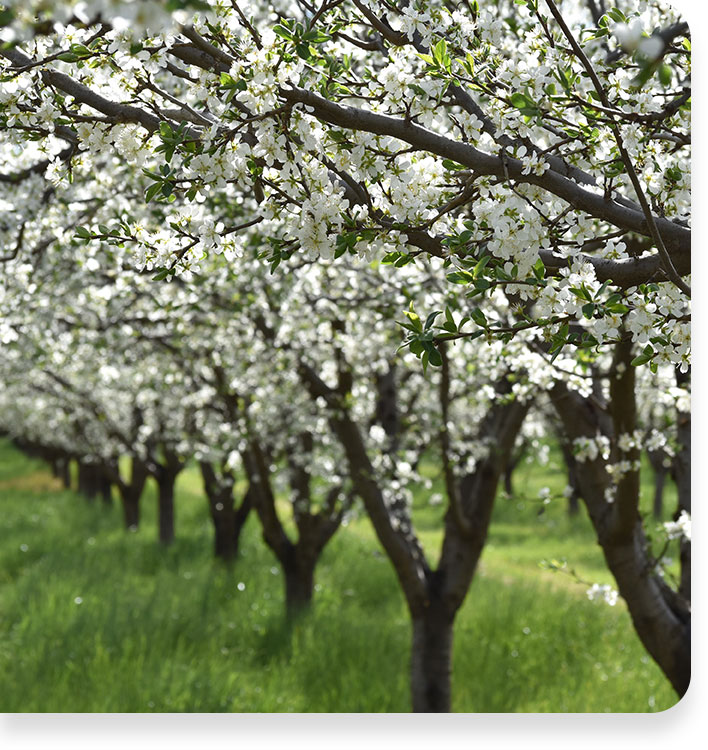

Blooming spring

Come spring, our orchards are covered in a fragrant canopy of white blossoms. This can be a precarious time for farmers, with late frosts or extreme wind a threat to the blossoms and next year’s fruit.

After seven to 10 days the blossoms will fall to the ground and the palette shifts to sprigs of bright green and deep red buds as new fruit forms and sets.

During late spring and early summer, farmers will irrigate and fertilise their orchards. Precise amounts of water can be drip-fed directly to the tree roots ensuring water isn’t wasted and the trees aren’t inundated or harmed.

Summer rush

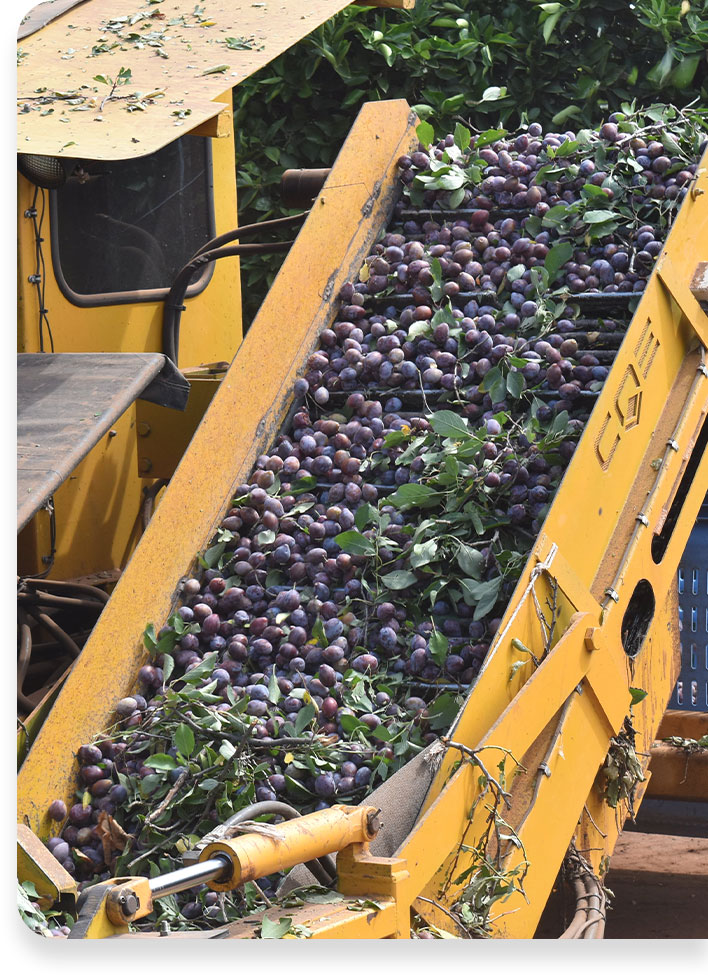

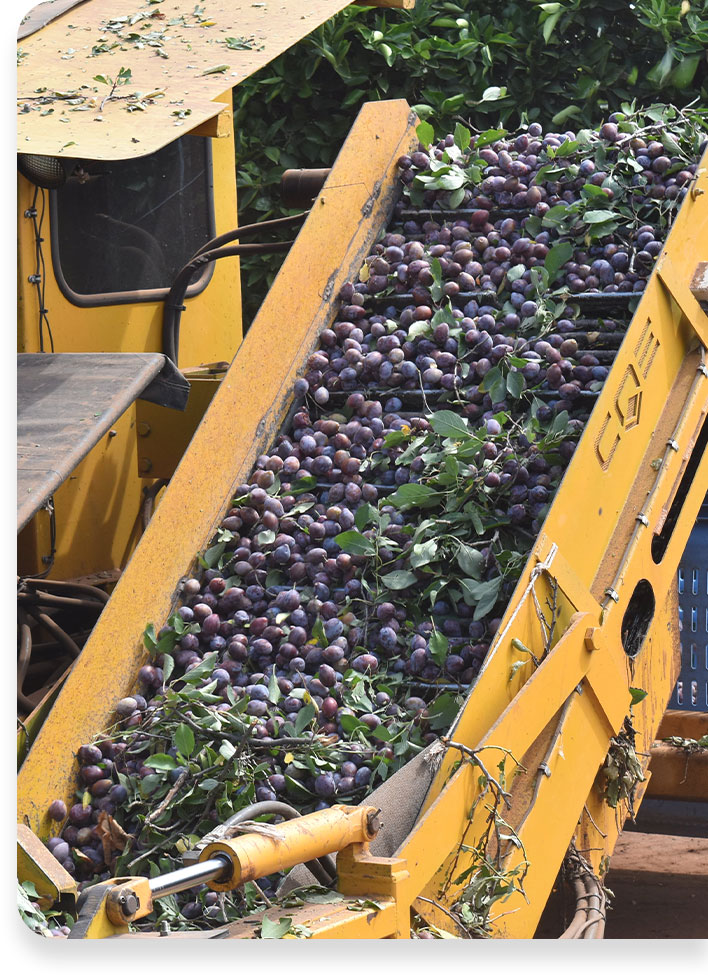

By mid-January, farmers are checking the orchards every few days to see if the fruit is ripe enough to pick. They will check the sugar levels and the firmness of the fruit.

Once the orchard hits the ideal sugar level, it’s go time. The ‘season’ has begun and from now on it’s a 24-hour-a-day job for four-to-eight weeks.

To deliver top-quality fruit, harvesting is largely done by machines. A mechanical shaker grabs a tree’s trunk and, in a matter of seconds, shakes the fruit onto a catching frame underneath. These machines are literally called ‘the shaker’ and ‘the catcher’. Then it’s a quick conveyor ride to bins where the fruit is ready for the shed.

Once the fruit reaches the shed it will be washed and placed on large wood and mesh trays. These trays are stacked on a tall trolley, with the trolley then pushed into the large tunnels of gas-powered ovens called dehydrators. One trolley will stay in the dehydrator for up to 16 hours, depending on the fruit’s sugar levels.

This system of tree to tray is efficient, fast, and highly sanitary. And while the processes haven’t changed all that much, it has become much faster and highly automated in the past 30 years to take up the challenge of more fruit being produced.

From the dehydrator, the prunes are ‘scratched’ off the trays mechanically and return to clean bins. And this is where the farmer often leaves them, to be stored in a cool, dark place waiting to be delivered to Australian processors like Angas Park, or Verity Fruits for grading and packaging.

Autumn